How It’s Made

How to Make Hash

Making hash combines old traditions with new techniques. Find out the different production methods used to make everything from classic hash to bubble hash.

Last updated October 6, 2025 | Published on April 6, 2021

Hash made its first appearance in the legal recreational cannabis market in 2020, but its history dates back thousands of years.

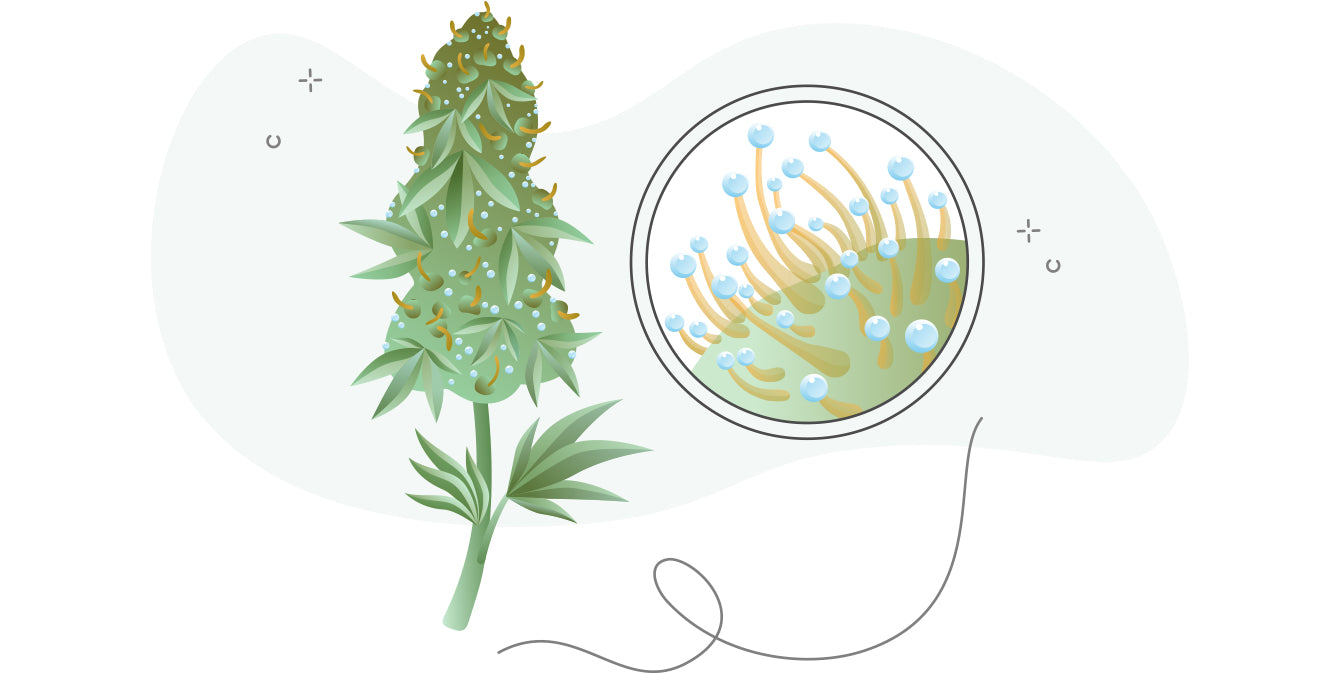

What is hash made of?

Made from the sticky, crystal-like trichomes found on the cannabis plant, hash is one of many types of cannabis concentrates, rich in cannabinoids and terpenes. It’s produced by collecting and compressing these trichomes into a solid or semi-solid form.

How are those resinous trichomes transformed into hash? Keep reading to find out.

How is hash made?

Traditional methods of making hash include:

- hand-rubbing

- dry sifting

- using ice water to separate the resin from the plant material (to make bubble hash)

The final product can vary in texture and potency, ranging from soft and sticky to hard and brittle, depending on the method and strain used. You’ll find pressed bricks, balls and strips; powdered and bubble hash; and hash-infused beverages and edibles at Authorized Cannabis Stores in Ontario.

Here’s a step-by-step of the hash production process.

Step 1: Selecting and preparing the flower

Before producers can start hash production, they have decisions to make about the cannabis flower they’ll use. Dried or fresh? Trim or whole plant? Single or multiple harvests?

Some producers turn to external growers to source whole plants from multiple harvests of unique strains and some trim from their in-house dried flower. Others use whole fresh plants from a single harvest (grown in-house), focusing on smaller buds and good trichome coverage.

Depending on each Licensed Producer’s unique process, the flower may be frozen immediately after harvest to maintain freshness and to preserve the trichomes (and the terpenes within).

Step 2: Collecting the concentrate

When the dried or fresh-frozen flower is ready, it’s time to separate the trichomes. There are a few different types of hash: bubble hash and dry sift hash are two of the most popular. Both are made without the use of solvents, and while the resulting product is similar, the processes are unique.

Dry sift

Dry sift hash is what it sounds like: The plant material is carefully brushed back and forth over a fine-mesh screen (or a series of ever smaller screens), letting the separated trichomes fall into a container beneath to be collected. Another variation of this simple dry sift process involves a tumbling machine with screens sized specifically for trichome glands.

Bubble hash

Bubble hash requires a more complex process, one that involves agitating the flower to separate the trichomes. The cannabis flower is typically placed in a mesh bag and soaked in ice water to rehydrate it. This is important because the goal is to separate the trichomes from the flower but not break the flower itself. Doing so would rupture cellular walls and release chlorophyll into the product.

The careful agitation is done by machine or by hand, using paddles. The water is then left to settle; the trichomes fall to the bottom of the tank (the sieve-like lining of the mesh bag keeps the unwanted plant material from escaping) where they’re drawn through a series of smaller filters.

Both production methods can take anywhere from a few hours to more than a day to complete. The resulting product is a concentrated collection of the plant’s trichomes. It contains high levels of cannabinoids and terpenes, which give it a light to dark golden colour. If more plant material is present, the hue can lean toward green.

The production methods create different variances in texture, too. The bubble hash process is thought to allow for a greater level of terpene preservation, making the resulting concentrate slightly more malleable than that produced by the dry sift method.

Step 3: Drying and pressing

Depending on how it’s extracted, the concentrate may be dried before it’s turned into hash. The concentrate may be quickly freeze-dried to remove moisture, which helps to both prevent mould and preserve the flavourful terpenes.

Transforming the concentrate into hash requires another step: heating and pressurizing. A typical process involves placing the concentrate in a mould that’s transferred into a heated press, ensuring firmness and uniformity. The specific pressure and temperature applied varies depending on the Licensed Producer’s unique process, as well as the amount of moisture in the concentrate. For example, it may be pressed at two to three pounds per inch (PSI), at a range of 40ºC to 60ºC, for four to 10 minutes.

The resulting solid brick or ball of hash can be broken apart and smoked in a pipe, a bong, a concentrate-specific vaporizer or a dried flower vaporizer with a concentrate attachment.

Step 4: Testing and packaging it up

As with all legal cannabis products, testing and quality assurance are crucial. It’s done at many stages, from flower to finished product.

If a Licensed Producer purchases cannabis from another LP to produce hash, that flower will come with a Certificate of Analysis (CoA), which includes details about potency, pesticides, contaminants and microbials. The plant material is tested once more before extraction.

The concentrate produced during extraction processes is often also assessed internally by Licensed Producers (to keep track of attributes like cannabinoid content and terpene profiles), as well as once it’s been pressed into hash. Gustatory and sensory testing is another part of ensuring quality in hash products.

Hash is typically packaged in a double container, with interior packaging to protect the delicate trichomes and exterior childproof packaging. Every product is affixed with federally required labelling, which includes the cannabis symbol, brand name, THC and CBD content, health warning message, lot number, ingredients, “packaged on” dates and bar code — details to keep consumers well informed. After packaging, the final product receives one more inspection to ensure safety for consumers.

Hash has a long history — and a bright future, with innovative technologies being combined with old-school techniques to produce new and interesting takes. As cannabis cultivars are bred specifically for extraction, look for more strain-specific hash options, as well as other innovative offerings.